Filling equipment

We offer a wide range of equipment for processing food and non-food products

The demand for Bag-in-box has grown significantly worldwide due to the strong desire of food and beverage manufacturers to provide longer shelf-life of their products, waste reduction and brand improvement. TEO UK Packaging Limited is actively working on the needs and trends of the market, and now provides you with a complete Bag-in-box solution in collaboration with the PROFRUIT MACHINERY.

TEO UK Packaging Limited offers high quality filling equipment. Our assortment includes automatic and semi-automatic machines, and, also, bin tippers, washers, elevator mills, belt presses, pasteurizers and screw conveyors. All these options facilitate the processing of fruit and vegetables and guarantee the efficiency of your production. We will gladly accompany you all the way through Bag-in-box project implementation.

Bag in Box and Super Pouch Filling Equipment

Automatic Bag in Box and Stand up Pouch filler AUTOFLOW 300

Affordable, user-friendly, mobile automatic machine AUTOFLOW300 is a perfect solution for medium and large-scale production. Guarantees high productivity and effortless operation. All the work is done automatically. Insert the bag into the filler and remove it in a few seconds.

- Capacity: 300 pcs. of 3L bags per/hour.

- Possibility of hot and cold filling.

- Supports wide range of formats: from 0,5 to 220L with different fitments.

- Option with integrated buffer tank available.

- Touchscreen panel.

- Repeatability of volumes with an error of ± 0,5 %.

- Adjustable filling table

- Mounted on pivoting wheels.

Semi-automatic Bag in Box and Stand up Pouch filler SEMIFLOW 300

Affordable, user-friendly, mobile semi-automatic machine SEMIFLOW300 is an excellent solution for small and medium-scale productions. Just place the fitment into the gripper and remove a filled bag from the machine. It is easy to install and operate with no specific requirements for intensive maintenance.

- Capacity: 300 pcs. of 3L bags per/hour.

- Possibility of hot and cold filling.

- Supports wide range of formats: from 0,5 to 220L with different fitments.

- Option with integrated buffer tank available.

- Touchscreen panel.

- Repeatability of volumes with an error of ± 0,5 %.

Adjustable filling table

Mounted on pivoting wheels.

TEO UK Packaging Limited provides Bag-in-box filling equipment specifically designed for liquid and pasty products

Our semi-automatic and automatic machines work perfectly for filling Bag-in-box packaging with juices, wine, vegetable oils, dairy products etc. However, their application is not limited to beverage and food industry. Our filling equipment is also suitable for chemical industry and filling such liquids as engine lubricants, detergents etc.

Both semi-automatic and automatic machines fit for hot and cold filling. Adjustable table consisting of conveyor rollers ensures smooth operation with a wide range of bags formats: from 0,5L to 220L. Touchscreen control panel with an intuitive interface facilitates machine installation, settings changes and maintenance.

Equipment for fruit and vegetables processing

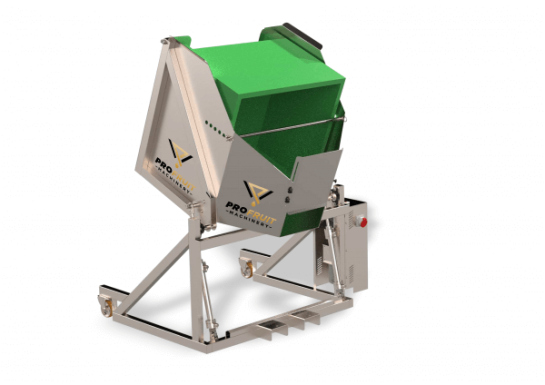

Bin tipper UNLOADER 500

UNLOADER 500 is designed and made to withstand the strains of lifting heavy and bulky containers.

- Hydraulic drive.

- Manual operation.

- Suitable for boxes with different dimensions.

- For cargos up to 500 kg.

- Mounted on pivoting wheels.

Fruit and Vegetable washer AQUA 3000

AQUA 3000 ensures gentle and efficient washing leaving the fruit intact.

- Capacity – 3000 kg/h.

- Washer cover can be opened for inspection and cleaning.

- Operation at the central command box.

- The speed of the washer is adjustable – the speed of the fruit washer dictates the capacity of the processing line.

- Gradual exchange of water during the washing.

- Long slide at the outlet for draining fruits and removal of dirt.

Fruit and Vegetable Washer Elevator Mill MAXIMILL 1000

MAXIMILL 1000 guarantees thorough washing and fruit milling before processing.

- Capacity – 1000 kg/h.

- Separate or integrated command box for operation of the machine.

- Sorting table for non-conditional fruits and vegetables.

- Water-spraying system for washing.

- Belt conveyor with water drainage and speed regulation system.

- Replaceable cutting grater/sieves.

- The mill does not damage the fruit seed.

Fruit and Vegetable Washer Elevator Mill MAXIMILL 3000

MAXIMILL 3000 produced for high-speed washing and fruit.

- Capacity – 3000 kg/h.

- Separate or integrated command box for operation of the machine.

- Sorting table for non-conditional fruits and vegetables.

- Water-spraying system for washing.

- Belt conveyor with water drainage and speed regulation system.

- Replaceable cutting grater/sieves.

- The mill does not damage the fruit seed.

Belt Press POWERPRESS 350

POWERPRESS 350 designed for continuous pressing of fruit and vegetable mass.

- Capacity: 350 kg/h

- Integrated pump and juice collection tank into the press itself.

- Integrated into the juice collection tank filtration sieve, so the juice is being filtrated even during the pressing stage.

- Belt press functions automatically. When the tank of the mass is full, all other machines which come before BP turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

- Air compressor and high pressure washer is included.

- Automatic cleaning of belt press 350 with high pressure cleaner, scraper and brush.

- Pneumatic lifting of the security cover of the belt press for easier access when cleaning.

Belt Press POWERPRESS 750

POWERPRESS 750 designed to dewater fruit and vegetable mass conserving the valuable ingredients during processing.

- Capacity: 750 kg/h

- Integrated pump and juice collection tank into the press itself.

- Integrated into the juice collection tank filtration sieve, so the juice is being filtrated even during the pressing stage.

- Belt press functions automatically. When the tank of the mass is full, all other machines which come before BP turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

- Air compressor and high pressure washer is included.

- Automatic cleaning of belt press 350 with high pressure cleaner, scraper and brush.

- Pneumatic lifting of the security cover of the belt press for easier access when cleaning.

Belt Press POWERPRESS 1000

POWERPRESS 1000 ensures that the fruit and vegetable mass is pressed quickly, reliably and hygienically.

- Capacity: 1000 kg/h

- Integrated pump and juice collection tank into the press itself.

- Integrated into the juice collection tank filtration sieve, so the juice is being filtrated even during the pressing stage.

- Belt press functions automatically. When the tank of the mass is full, all other machines which come before BP turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

- Air compressor and high pressure washer is included.

- Automatic cleaning of belt press 350 with high pressure cleaner, scraper and brush.

- Pneumatic lifting of the security cover of the belt press for easier access when cleaning.

Belt Press POWERPRESS 1500

POWERPRESS 1500 guarantees optimal juice extraction achieving its full flavour.

- Capacity: 1500 kg/h

- Integrated pump and juice collection tank into the press itself.

- Integrated into the juice collection tank filtration sieve, so the juice is being filtrated even during the pressing stage.

- Belt press functions automatically. When the tank of the mass is full, all other machines which come before BP turn off automatically. When the juice tank is full, juice pump pumps the juice into the tanks.

- Air compressor and high pressure washer is included.

- Automatic cleaning of belt press 350 with high pressure cleaner, scraper and brush.

- Pneumatic lifting of the security cover of the belt press for easier access when cleaning.

Diesel Pasteurizer HEAT 350-500

HEAT 350-500 designed for quality stability of your product throughout its storage period.

- Capacity: 350-500 liters/hour

- Maximum heating temperature of diesel pasteurizer – 90 ºC.

- Juice come into the tubular spiral which is surrounded by hot water (Tube-in-Tube technology).

- Spiral is integrated into the boiler which provides saving of space and prevention of heat loss when pumping the water into external heat exchanger. This saves the heating energy up to 15-20%.

- Automatic water temperature control with a digital thermostat.

- Automatic regulation of juice temperature: it is easy to change the juice temperature (filling temperature) on digital display.

- Suitable for viscous media, virtually maintenance free because there is no seal.

- Possibility of using diesel or natural gas.

Diesel Pasteurizer HEAT 900-1100

HEAT 900-1100 is a heat treatment equipment to ensure 100% food safety.

- Capacity: 900-1100 liters/hour

- Maximum heating temperature of diesel pasteurizer – 90 ºC.

- Juice come into the tubular spiral which is surrounded by hot water (Tube-in-Tube technology).

- Spiral is integrated into the boiler which provides saving of space and prevention of heat loss when pumping the water into external heat exchanger. This saves the heating energy up to 15-20%.

- Automatic water temperature control with a digital thermostat.

- Automatic regulation of juice temperature: it is easy to change the juice temperature (filling temperature) on digital display.

- Suitable for viscous media, virtually maintenance free because there is no seal.

- Possibility of using diesel or natural gas.

Screw Conveyor for Pressed Mash

The conveyor transports the leftover mash from pressed fruits, berries or vegetables to a preferred storing tank.

- Produced with a closed tunnel.

- Conveniently transports leftover pressed mash from press.

Request information

Fill out the form and we will contact you shortly